High Quality Gypsum Powder Calcination Production Line for Making Gypsum Board

Basic Info

| Model NO. | WX-GP |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Application | Making Gypsum Board |

| Advantage | Easy to Operate |

| Configuration | Top |

| Usage | for Producing Gypsum Powder |

| Product Name | Gypsum Powder Making Machine |

| Control System | PLC |

| Transport Package | Suitable for Long Distance Transportation |

| Trademark | wuxing |

| Origin | China |

| HS Code | 84742090 |

| Production Capacity | 5-6 Sets Per Year |

Product Description

Product Description

FULL AUTOMATIC GYPSUM POWDER MAKING MACHINEOur factory have been specialized in making full automatic gypsum powder production line for more than 13 years with the up-to-date technology and experienced research and develop team.

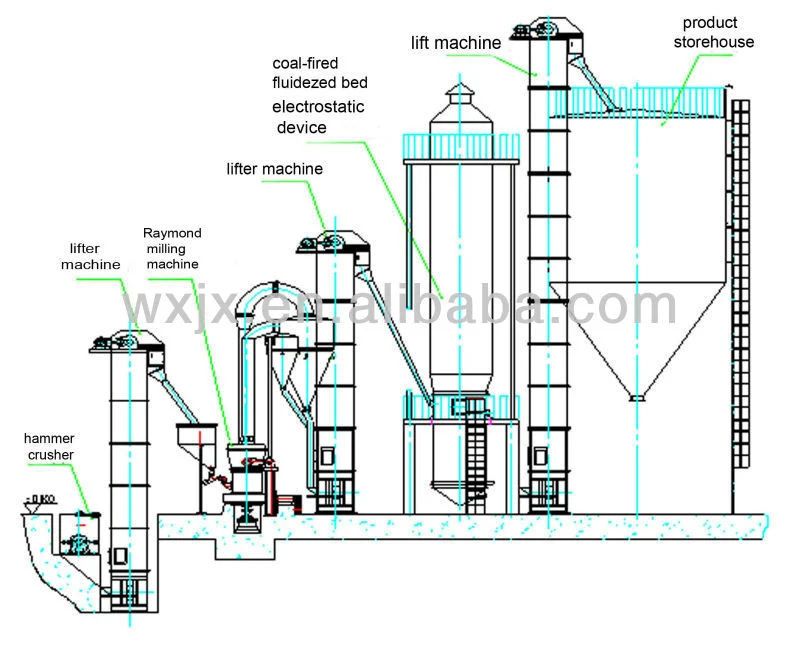

Feeding and crushing Feed the gypsum rock to the raw material storage bin of the auto feeder by using loader.Then it will be transferred to the crusher to be crushed.Milling

Byusing lifter,the gypsum will be transferred to silo and then transferred to Raymond mill by using electromagnetic feeder. Then usepulsed dust collector to eliminate the dust. Calcining

Analytical engine will be used to control the fineness of gypsum powder.By using lifter,it will be transferred to fluidized calciner. The conductive oil which has been heated by the boiler will be the themal source. Highpressure pressure blast which is from the roots blower will make sure that the gypsum powder insider the kiln is always boilingand heated evenly. Loading

After heated,the gypsum powder will be transferred to the bin to be homogenized storage then transferred by tank car or packed and stored.

Process flow chart

Quality standard

The quality of building gypsum is in accordance with Chinese National Standard "Gypsum Powder" (GB9776-2000), and should meet the following requirements:

| No. | Item | unit | Indices |

| 1 | Initial time | min | ≥6 |

| 2 | Final time | min | ≤13 |

| 3 | Bending strength of 2 hours | MPa | ≥2.0 |

| 4 | Content of CaSO4·2H2O | % | ≤5% |

| 5 | Content of CaSO4·1/2H2O | % | ≥75% |

| 6 | Content of CaSO4III | % | ≤5% |

Packaging & Shipping

1. Suitable for long distance transportation 2. Small or key parts loaded in iron boxes 3. Iron boxes with welding 4. Naked 5. Please mark it in the sales contract for special package

Detailed Photos

Main Features

Brief Introduction Natural gypsum generally includes dehydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally, we get semi-hydrated gypsum through heating the dehydrate gypsum. Main Technology gypsum mine ->first breaking ->second breaking ->grinding ->calcining ->aging ->finished products (CaSO4.1/2H2O) Raw Materials Content of CaSO4.2H2O in gypsum mine 80%

Company Profile

* The predecessor is stated-owned enterprice,was built in the 1970s.* A large manufacturer of integrated supply dedicated in researching,manufacturing, trading of building material machinery and construction materials .* CE approved by the EU * ISO 9001 certificate *We have professional team and rich experience.* We provide perfect after-sales service to solve customers' worries.

FAQ

1

Q:Are you a factory or trading company?

A:We are a factory.

2

Q:Where is your factory located? A:Our factory is located in Shijiazhuang, Hebei Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

3

Q:How can I know more about the product?

A: We are honored to send you some pictures and videos about our product. And we welcome every customer visit our factory.

4

Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the beginning to the end. Our factory has gained CE and ISO9001 authentication.

If you have any doubt, pls contact me. Lucy Dong