Category

China Factory Engineers Available Gypsum Board Production Line

China Factory Engineers Available 2014 Gypsum Board Production Line Introduction of gypsum board/panel production line:

Basic Info

| Model NO. | DCIB500 |

| Product Type | Gypsum Board Making Machine |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Screw Design | Single-Screw |

| Certification | ISO 9001:2008 |

| Condition | New |

| Customized | Customized |

| Automation | Automatic |

| Tolerance | 1.0mm |

| Type | Gyspum Board Production Line |

| Product | Gypsum Board |

| Raw Material | Natural Gypsum Powder |

| Capacity | 2million Sqm/Y-30 Million Sqm/Y |

| Fuel | Natural Gas, Coal, Heavy Oil, Diesel |

| Transport Package | Seaworthy Packing |

| Specification | ISO9001 |

| Trademark | DCI |

| Origin | China |

| HS Code | 8474809010 |

| Production Capacity | 4 Sets Per Year |

Product Description

China Factory Engineers Available 2014 Gypsum Board Production LineIntroduction of gypsum board/panel production line:

1. Production capacity: 2 to 20 million m2/year

2. Raw materials for production:

Gypsum, shielding paper, modified starch, foaming agent, glue and water

3. Fuel: Natural gas, diesel, heavy oil, coal

4. Specification of final product:

Thickness: 8mm-20mm

Width: 1200mm, 1220mm or 1250mm

Length: 1800-4500mm (adjustable)

5. Raw Material Consumption

(Based on 12.5 mm gypsum board for reference)

| Item | Consumption |

| Gypsum powder(semi-hydrated gypsum CaSO4·1/2H2O) | 7.5kg/m2 |

| Protective paper | 0.4-0.48kg/m2 |

| Gypsum board adhesive | 0.052kg/m2 |

| Foaming agent | 0.011kg/m2 |

| Glue | 0.005kg/m2 |

| Electricity | 0.4kwh/m2 |

| Water | 5.9-6.2kg/m2 |

| Natural gas (8200 kcal/ m3) | 0.31 m3 /m2 |

| Compressed air | 0.18m3/m2 |

| Gypsum | 6.8kg/m2 |

| Shielding paper | 0.48kg/m2 |

| Modified starch | 0.035kg/m2 |

| Foaming agent | 0.008kg/m2 |

| Glue | 0.005kg/m2 |

| Fiberglass (optional) | 0.025kg/m2 |

| Electricity | 0.3kwh/m2 |

| Water | 4.8kg/m2 |

| Heavy oil (11000kcal/kg) | Heat consumption~3800kcal/m2 |

| Natural gas (8500kcal/ m3) | Heat consumption ~3800kcal/m2 |

6. Sucessful cases:

We have successfully delivered many gypsum board production lines to UAE, Oman, Uzbekistan, Russia, and Iran.

7. Payment conditions:

A. Payment terms: 30% T/T in advance; 70%L/C or T/T

B. We can provide quality guarantee;

C. Kunlun bank account available to make convenient for Iranian clients

About DCI:

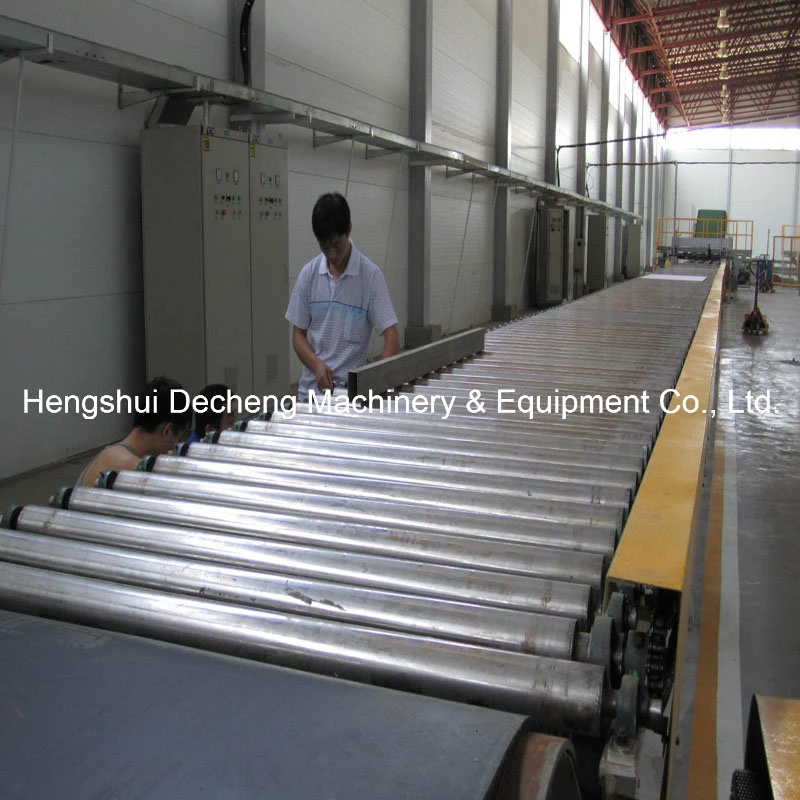

Decheng Group is incorporated of three companies: Hebei Decheng International Trade , Hengshui Decheng Machinery&Equipment and Qinhuangdao Dadi Engineering

Hengshui Decheng Machinery&Equipment has three workshops: machining workshop and casting workshop and electrical workshop. These three workshops mainly complete the manufacture and fabrication of machines and electrical control for production lines. In 2008, our company passed ISO9001 quality system certification. Our company has our complete professional team specialized in design, manufacturing, supply, installation and commissioning, and we can accomplish the matched electrical control system by ourselves. Moreover, our company owns our share-controlled processing base.