Automatic POF/PE Film L Type Shrink Tunnel Heat Shrink Shrinking Packing Packaging Wrapping Machine

Basic Info

| Model NO. | Lb-726/Lb-728/Lb-729 |

| Warranty | 1 Year |

| Application | Food, Commodity, Machinery & Hardware, Textile, Alcohol, Toy, Chemical, Apparel, Gifts & Arts, Dining, Medical |

| Packaging | Film |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Manner of Packing | Four Side Seal Type |

| Adjust Speed | Electronic Speed Control |

| Type | PE/POF Shrink Film Machine |

| Heating Mode | Stainless Steel Heating |

| Packaging Material | Film |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Usage | Outer |

| Packing Size | 50-400 X 50-280 X 2-80 |

| Packing Speed | 40-60(Bag/Min) |

| End Bar Seal Size | 450 X 335 |

| Transport Package | Wooden Case |

| Specification | 1485 x 1320x 1230 |

| Trademark | OEM |

| Origin | Guangdong, China |

| Production Capacity | 10000 |

Product Description

Automatic L-Bar Sealer

Automatic L-Bar Sealer is an entry-level automatic sealer which provides an economical, durable and easy-operated solution for packaging. It is also widely applicable to various industries such as toys, cosmetics, tools, foods, stationeries, daily commodities, electric appliances, etc. With the uniqueness of the perforation system, it has been successfully granted us a leading position in the industry.

Features

• A broad spectrum of products can be packaged• Cost-effective Automatic packing solution• Safety protection and alarm attached• The sealing system is capable of performing smooth and firm sealing line.• Easy operation and maintenance

Specification

Model | LB-726 | LB-728 | LB-729 |

Machine Szie LxWxH(mm) | 2000x1190x1480 | 1795×990×1570 | 1890x1335x1290 |

Packing size LxWxH(mm) | (100~530)×(60~400)× (5~120) | (100~450)×(60~350)× (5~120) | (60~560)×(60~400)×(10~160) |

Sealing bars size LxW(mm) | 640x512 | 565×460 | 630x520 |

Maximum Films Width (inches) | 22" | 23" | 27" |

Power | 220V, 1P, 3.5Kw | 220V, 1P, 3Kw | 220V, 1P, 3Kw |

Packing capacity (packs/min) Depends on products. | Max. 26 | ||

Pneumatic (NI/min) | 60 (6bar) | ||

Optional Value

We also provide a range of optional upgrades for the machines. Let's find out what extra value you may need.

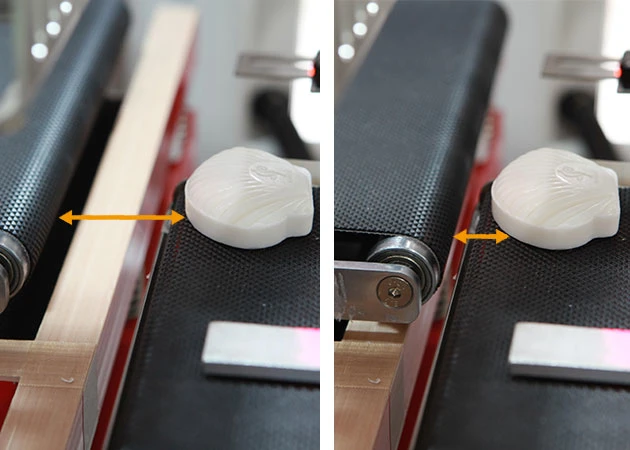

The distance between the front and rear conveyor belt can get closer for packing small products. When sealing happen, the rearconveyor will pull back for sealing bar to go downward.

This option offer user can adjust the front and rear conveyor speed on L-bar sealer. When dealing with unstable or slippery surface product (such as bottles and a pile of books), the inertia of conveyor may affect the product alignment. Slow down the conveyor speed can improve this problem.

Stainless steel version

Stainless steel machine are available allow the machine to be working stably under high moisture and low temperature working condition.

To use with color printed films for ensure preset bag length per pack.

Feeding devices with grouping function are specially designed to feed products to form a multi packing. Several products can drive together on the same time to prohibit misalignment happen. Packaging quality is improved because of this. It can increaseproduction speed compare to feed multi products by hand. Connecting to the existing production line can accomplish a fully automatic production.

Flight bar conveyorA guide rail pushing system is employed to pushing product in muti-packs format. Depends on products height and shape, different guide rail pushing systems are available.

Finger conveyor

(lug conveyor)

Finger conveyor contains quick change flight lugs with stainless steel surface. With product guide rail, it is mostly used for driving a cluster to fit a wide range of products. Program connected to subsequent shrink wrapper and missing products detection is provided. Tailor made in different specifications are available.

It is designed for handling all kind of booklets, mail pieces, phone card, magazine, etc…products can be fed individually to other conveyor for subsequent process. Feeding speed can control independently for variety of usage. Systematically connect with shrinkwrapper forms a complete automatic packing line.