Category

Circular Saw Blade Grinding Machine for Tct Face & Top Angle Sharpening

TFE800 CNC-controlled TCT Top and Face Sharpening Machine Application: This model is designed for resharpening service o

Basic Info

| Model NO. | TFE800 |

| Automatic Grade | Automatic |

| Cylindrical Grinder Type | Plunge Cylindrical Grinder |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Saw Blade Diameter | 110~650mm(Max700mm) |

| Hook Angle | 0°~ -27° |

| Top Angle | 8°~30° |

| Chamfer Angle of Top | 45°~-45 |

| Chamfer Angle of Face | 30°~-30° |

| Bore Diameter | 12-120mm |

| Wheel Diameter | 125mm*32mm |

| Wheel Speed | 4000~5000r/Min |

| Grinding Speed | 1~20mm/S |

| Power | 4kw |

| Voltage | AC 380V-50Hz/220V-60Hz |

| Weight | 1600kg |

| Item | Tct Saw Blade Sharpening Machine |

| Application 1 | Sawmill |

| Application 2 | Saw Blade Grinding Machine |

| Transport Package | Water Proof + Wood Carton |

| Specification | 1800 *1200 *2030mm |

| Trademark | TORSEL |

| Origin | China |

| HS Code | 8460310000 |

| Production Capacity | 5000units/Year |

Product Description

TFE800 CNC-controlled TCT Top and Face Sharpening MachineApplication: This model is designed for resharpening service of carbide tips top and face angle grinding,precision is controlled below:0.02mm, efficiency is 4-20s/tip.

High-level productivity & precision grinding machine for TCT tips grinding.

• Saw Dia: <800mm

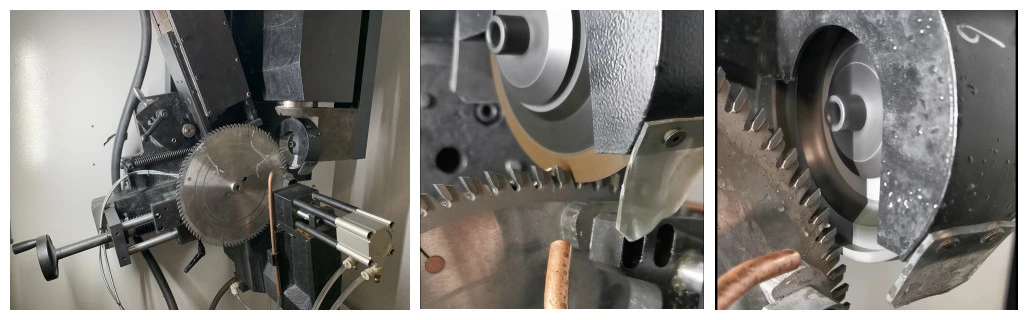

• Function: Tooth Top and Face angle sharpening

• Precision: <0.02mm

• Pitch: <105mm

• Model: TFE800

• High precision, more function & more productivity, PURCHASE is cost-effective.

• Cooperation Company

Advantages of saw blade sharpener

• More precision- grinding precision: <0.02mm,be impressed by the higher accuracy.

• More efficiency- experienced productivity on a higher level

• More user comfort- simplify your work

• More flexibility-for precision in any requirement

• More Function- grinding TOP & FACE of saw blade

Technical Premeter

| Description | Sepecification |

| Saw Blade Diameter (mm) | 800 |

| Face Angle (°) | 0 ~ -27 |

| Top Angle (°) | 8 ~ 30 |

| Chamfer Angle of Top (°) | 45 ~ -45 |

| Chamfer Angle of Face (°) | 30° ~ -30° |

| Tooth Pitch (mm) | < 120 |

| Bore Diameter (mm) | 12-120 |

| Wheel Diameter (mm) | 125*32 |

| Wheel Speed (r/min) | 4000~5000 |

| Grinding Speed (mm/s) | 1~20 |

| Grinding Effciency for Face Angle (s/tip) | 4.5 |

| Precision (mm) | <0.02 |

| Power (Kw) | 4 |

| Dimensions (mm) | 1800 *1200 *2030 |

| Weight (kg) | 1600 |

Configuration

| Ball Screw | IF(Germany) |

| Roller Guide | HIWIN(Taiwan) |

| Pneumatic Parts | SMC(Japan) |

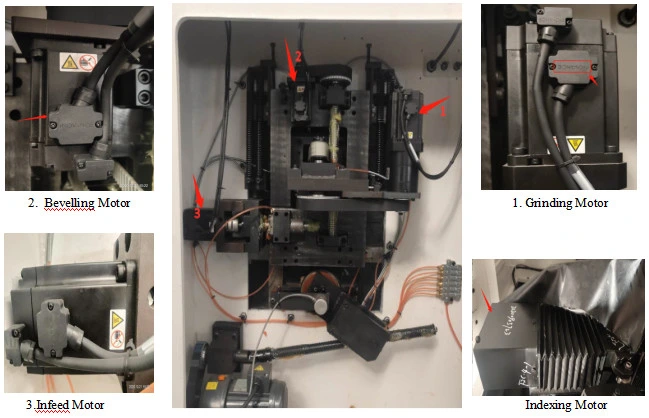

| Servo Motor | Inovance |

| PLC | Inovance ARM600 |

| Harmonic Drive | Inovance |

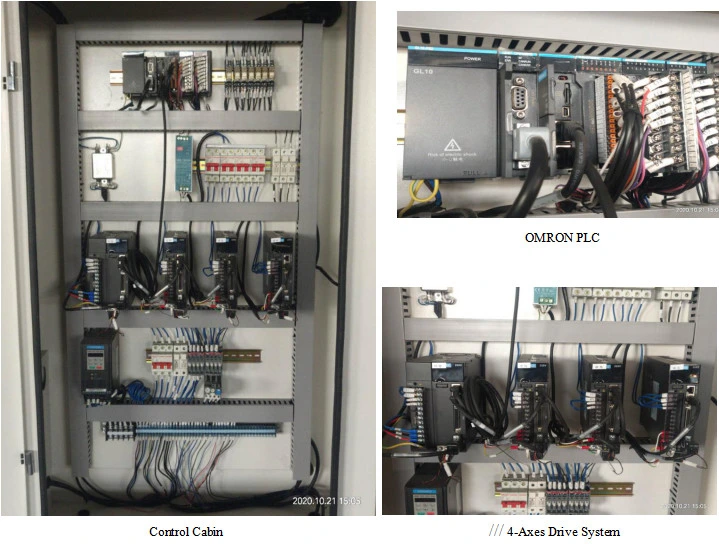

Configuration4-axes CNC Controlled with 4 servo positioning system,ensure the angle grinding with higher accurate.

CNC Control- High Precision is flexible to control ultra-precision grinding as requirement. HANDWHEEL is good for faster adjustment.

3-D Models

If you need this model,please contact with me:

Package

FAQ

1. Whats your cooperation companys?2. What doesTORSEL offer?- High Productivity & Efficiency GrinderTORSEL Sharpeners controlle grinding precision:<0.025mm,griding efficiency:4-20s/tip, top and face grinding can be finished in one set-up.It is both working for saw blade manufacturing and resharpening service- Best quality with top configurationPlease refer to configuration of grinders,all the components are top brand in industrial,this makes the grinder operate with stability and longer service life.- High Precision<0.025mm3. How is the performance of TORSEL saw blade grinding machine?- TORSEL saw blade grinding machine process tool with excellent precision <0.015mm,the service life is upto 7-15 years.4. How to do if I can not operate?If you have operation problem when you get the sharpeners, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

5. How to get spare part after warrantyOne of our sharpeners is working for Korea Resharpening service for 15 years,we still serve with after sale service.If buyers need spare parts,or there is any problems after waranty, we will always responsible for TORSEL sharpeners, including find problems, send spart parts, and teach you to replace the parts.

If you need to learn any information We are online for your service.